Blog

A deep-dive into Aionics’ customer testimonials and the capabilities that inspire them

“Aionics develops new electrolyte formulations for us way faster than our large electrolyte suppliers can.”

“Aionics is the only company that has mastered the ability to optimize electrolyte formulations over critical safety and flammability criteria.”

“Most companies do high-throughput experimentation because they don’t know how to solve the problem. But Aionics solves the problem first, and then does high-throughput experimentation to find the best solutions.”

These are the kinds of testimonials we live for!

These are all comments that have been recently made to us by our customers. We love to hear that we are creating singular value for our customers that no one else on the market can. Each of these three comments represents a special superpower of Aionics — so let’s dive into each statement, one-by-one, to see what our AI-driven design platform Ami is capable of.

“Aionics develops new electrolyte formulations for us way faster than our large electrolyte suppliers can.”

As the power of artificial intelligence and high-performance computing grow exponentially, our capacity to engineer the physical world should grow exponentially too. With Aionics as a partner, this is a reality: developing new electrolyte formulations that hit ambitious, never-before-seen performance targets can be done faster than ever with the help of AI. But, for too many of our customers, they are stuck waiting on their electrolyte formulators to try to innovate on their behalf by moving at the slow pace of human intuition-driven trial-and-error.

Only a small number of formulations will ever be capable of achieving ambitious performance targets. Finding those solutions among a sea of 10 billion commercial molecules requires fast and accurate AI models that can search through the vastness of chemical space to find the hidden gems. But electrolyte formulators often have a small catalog of chemicals they can manufacture and sell — so they naturally will only search through this space.

Conversely, Aionics is a digital formulator, meaning that we can formulate new electrolytes by drawing from universe of chemicals from everyone’s collective catalogs — and then find the formulator who is best-suited to manufacture the winning formulation at scale. And we can use AI to find those winners orders of magnitude faster than anyone else. We have over 10 billion molecules in our library — and our only motivation is to find the best combination that works for you.

Our customer gave us a simple performance target: identify ways to modify our electrolyte to improve a key electrolyte property by a certain amount (name of property and targets confidential). Within three months, Aionics had identified a formulation that improved that same property by 5.3x the target value — and in the process, also found more than 10 alternative formulations that exceeded the 1x target benchmark as well!

Curing what ails batteries is a lot like curing what ails humans — we aren’t going to find breakthrough cures by looking for new ways to combine the same 10 drugs in different ways. We need to navigate the entirety of the quantum world to find breakthrough solutions. That’s what Aionics is built to do — and it’s why our customers are noticing that an AI-driven, closed-loop chemical optimization system can out-innovate entire electrolyte manufacturers with thousands of scientists on staff.

“Aionics is the only company that has mastered the ability to optimize electrolyte formulations over critical safety and flammability criteria.”

There are plenty of material and molecular design tools out there — and some even directly targeted at electrolyte design. But there is only one company that has demonstrated successes in designing electrolytes around the complex but important criteria of safety and flammability: Aionics.

Battery flammability is a major concern across sectors: New rules seek to limit the likelihood of on-board Li-ion battery fires on commercial flights. Stringent battery flammability standards must be met in order to import EVs into China. Companies in the nascent eVTOL industry will need to demonstrate redundant battery safety in their aircraft in order to get FAA certification to fly passengers.

But take a look at existing electrolyte tools and you’ll see a conspicuous lack of tooling to help with any of these problems. You’ll see lots of guidance on how to change the salt concentration to tune ionic conductivity, or how to predict the electrochemical stability window of individual molecules, but you won’t see anything about whether a new additive will help decrease an electrolyte’s self-extinguishing time or whether replacing a functional group of a co-solvent will prevent the cell from going into thermal runaway during a nail penetration test.

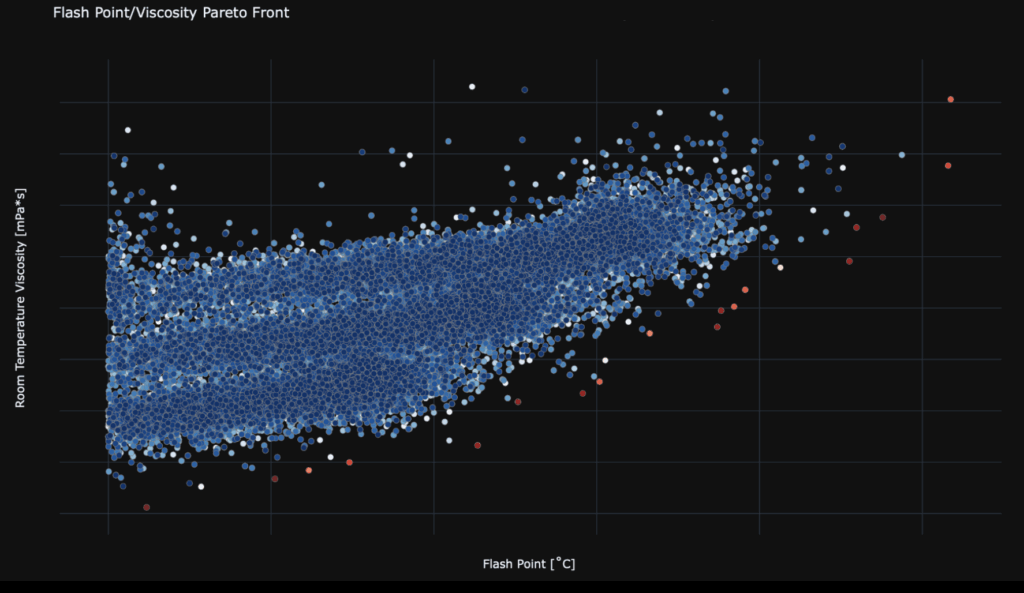

This is where Aionics excels–and, in fact, where we’ve carved out a compelling niche. In our work with automotive and aviation customers, electrolyte flammability and cell safety has been a major focus area. Our tools can generate new formulations (or modifications to existing formulations) that maximize the flash point and decrease the viscosity simultaneously — an optimization that is generally thought to be impossible, and one which we successfully performed for this customer.

Must safety come at the expense of power? Aionics was able to find the best of both worlds. In this customer case study, we computed the flash point and viscosity of hundreds of thousands of candidate formulations in a matter of minutes. The formulations on Pareto front of the two properties are shown in red. This helped our customer find solutions that optimize for safety at minimal performance impact.

“Most companies do high-throughput experimentation because they don’t know how to solve the problem. But Aionics solves the problem first, and then does high-throughput experimentation to find the best solutions.”

Here’s something to consider: our state-of-the-art electrolyte testing robot can characterize a candidate new electrolyte in about 8 minutes with no human intervention. That’s blazingly fast by industry standards — but not quite fast enough to make a dent in the chemical universe. That’s why we begin our design process with an AI-driven computational search of chemical space first — at a rate of 3,000 formulations per second. This ensures only the best of the best candidates make it down to the lab for real-world validation.

Here, we screened tens of thousands of candidate electrolyte additives based on their predicted impact on the cycle life of the customer’s cell, the electrochemical stability window of the additive, and the predicted cost to procure. While most high-throughput searches usually are code for “trying lots of things at random until we find a winner,” Aionics builds best-in-class, validated models for predicting key properties first before starting a high-throughput search. And these models include historically difficult-to-predict properties like cycle life and cost, as seen here. We believe testing lots of new formulations at random will never make a dent in a chemical universe made up of over 10 billion unique molecules; you need to have good AI models to co-pilot you through the vast depths!

This customer testimonial reflects a reality about our industry: although there is much excitement over self-driving labs and high-throughput experimentation, these tools are not truly paradigm-shifting — they represent perhaps only a 10x improvement over the speed of human scientists. To really change the game, we need a million-fold speedup over manual experimentation. This is why our AI layer is so important — and why self-driving experimentation is actually only the supporting actor and not the star of the show.

Furthermore, our AI models incorporate criteria that no other platform can. Sure, there is the safety criteria we mentioned above — but we can go further. Measuring the cycle life of an electrolyte formulation in a given cell can take months of time. But with a bit of training data, our platform calibrates internal models to learn how to predict long-term cycle life directly from the identity of the electrolyte formulation — by enriching these real-world data with electronic structure calculations and data mining the result for useful trends. The result is a billion-fold speedup in predicting battery degradation: cycle life is predicted in 0.0003 seconds per formulation instead of 3 months.

Like what you see here? Get in touch and let’s explore what we can do together. Contact us at partnerships@aionics.io.

By

Chief Executive Officer

Newsletter Registration

Subscribe to our newsletter and stay updated with the latest from Aionics.