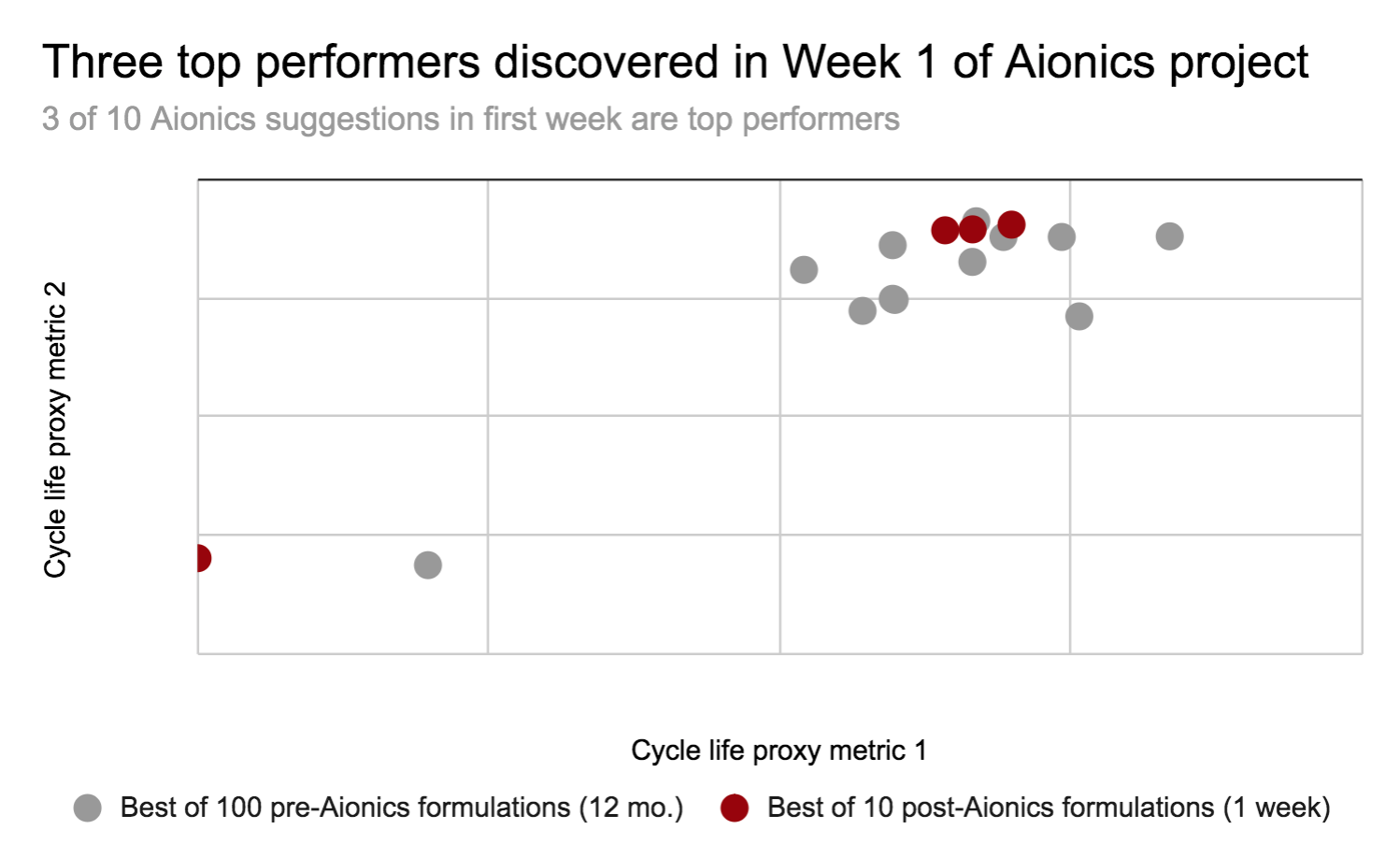

After spending over a year sampling over 80 different electrolyte formulations, looking unsuccessfully for the one that would meet two performance metrics, one non-Li battery cell manufacturer decided to begin a new partnership with Aionics. By using the Aionics platform to ingest the data that had been measured to-date, build models to predict battery degradation as a function of the electrolyte components and their concentrations, and then apply the models to hundreds of candidate formulations, this manufacturer found immediate success: three of the first ten new formulations suggested by Aionics scored as high performers on both performance metrics. The company CTO later stated the partnership with Aionics enabled them to hit their desired performance metrics with 10x lower cost, time, and effort. This effort is notable because the battery chemistry is completely novel: none of the scientific literature or physics-based models developed for Li-ion batteries were relevant, so a data-driven approach was necessary — and Aionics delivered.

Newsletter Registration

Subscribe to our newsletter and stay updated with the latest from Aionics.